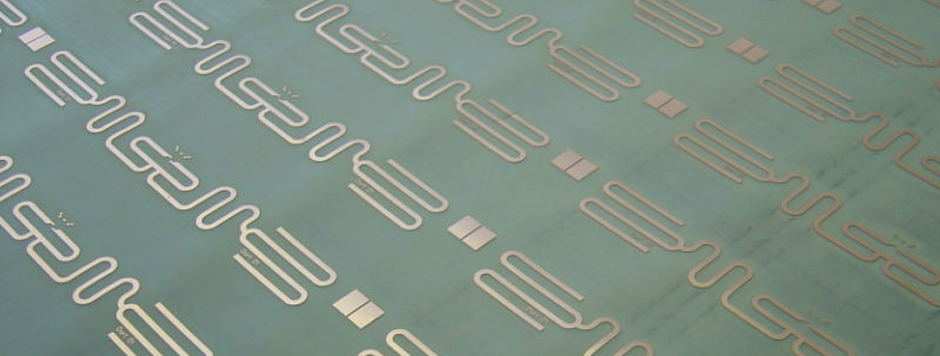

Radio Frequency Identification (RFID) is an automatic identification method that stores and remotely retrieves data via an RFID tag or transponder. The RFID inlays are simply a tag on a bendable substrate that is ready for conversion to a smart label. RFID commonly the Radio Frequency Identification is the innovative technology that is being famous day by day for the product identification and data storage where the barcode technology fails to work. If explained in technical terms then the RFID inlays are simply a tag on a flexible substrate that is ready for conversion to a smart label. This label can extend the elementary operating of RFID by combining it to the barcode technology.

The RFID inlays are composed of integrated circuits and dipole antenna that are being attached with the help of strap. The RFID dry inlay are commonly attached to the substrate backing material called web. The antenna that is used in the inlays to attach with IC can be made of silver, aluminum and copper. RFID wet inlay is the type that have an adhesive backing with a cleared or colored top surface. The type of surface that is commonly used to make RFID labels is of PVC or PET. The inlay is placed on the back of the label away of the adhesive side to make the label adhesive continuously.

The placing of a wet inlay to each label is very specific considering each RFID printer. This is also done to minimize the risk of damaging the RFID inlays while printing. These days the RFID implementation is present with the advantages of quality performance and cost factors that is simply low. An RFID programmer encodes information onto a tiny microchip within a thin RFID tag that looks much like a normal pressure-sensitive carton label. RFID readers that work on the same protocol as the tag are distributed at key points throughout the supply chain. Readers relay the codes to a host computer as the carton passes through an RFID portal or moves along a conveyor anywhere in the supply chain.

These readers activate the tag, causing it to broadcast high frequency radio waves within bandwidths reserved for RFID usage by individual governments. CXJ RFID label or tag integrity is maintained as it is underneath the actual label, inserted within the packaging or encased in a durable material. Each RFID label or tag can be read even when multiple tagged products are sealed inside a carton (for example). RFID Labels and Tags are often orientation-insensitive, meaning the tagged item not only does not have to be seen to be read, but can be in any orientation. RFID tags operating 902 to 928 MHz band are referred to as ultra high frequency (UHF) tags.

RFID labels and tags provide a unique ID for each and every product and can be associated with individual information such as the manufacturing location; date shipped, lot number, etc. If this is your first RFID project, it is important to work with an experienced RFID Systems Integrator to help lay out the framework for the project and offer guidelines on the type of solutions that should be considered. The ETSI recommended UHF RFID operational frequencies for Europe are between 865-868 MHz.